Since the mid fifties, Pallmann is designing, building and selling pulverizing systems and mills for the production of finest plastic powders worldwide. As the inventor for pulverizing of heat-sensitive plastics under ambient temperature, Pallmann supplies different pulverizing technologies that optimally meet market demands and that are continuously improved.

Pulverizing of heat-sensitive materials and thermoplastics such as H-PVC, LLDPE, LDPE, HDPE, PP, EVA , rubber, PA and ABS is necessary in many industries.

The production of finest powder for rotational moulding, for the production of masterbatch and for coating of textiles and metals requires the adherence to necessary requirements such as bulk density, uniform particle size, particle size distribution and flowability.

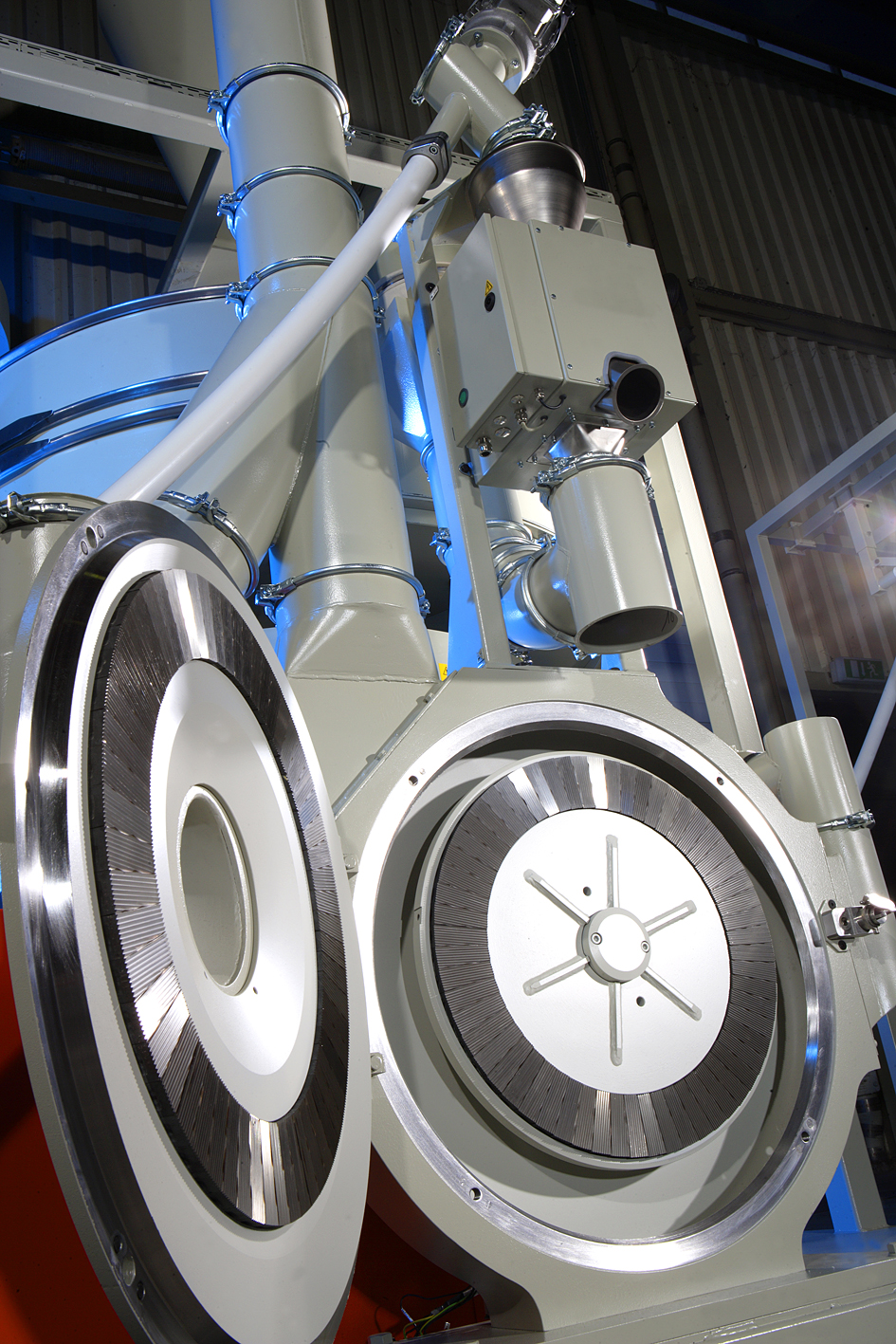

Pulverizing systems, type PKM and PM are high capacity systems. They allow the adherence to the requirements according to the customer’s demands in the corresponding markets. The PolyGrinder® installed in each system is the core technology. Powders so produced from different feed materials distinguish themselves through high quality and flowability.

The efficient downstream process in complex rotational moulds, coatings and in pipe- and profile extrusion is thereby simplified. New mill housings and easy to clean systems allow quick and thorough cleaning when changing product or colour during production of masterbatches.

The newest generation of this series receives the EcoAdvanced™ label. Only innovative Pallmann products which meet both the highest quality demands of the market and which distinguish themselves by special efficiency receive this award. Polygrinder® stands for high throughput capacity at low energy consumption. The individually exchangeable grinding elements and the easily accessible exterior grinding gap setting guarantee high flexibility in production and a quick adaptation of the particle size to the latter utilization of the powder. Based on material and requirement, grinding disc diameters up to 800 mm in combination with high throughput capacities of up to 1500 kg/h can be supplied.

In the company-owned research and technology center, pulverizing sytems are available for test runs, process improvement and for research of promising, new products and material. Material supplied by the customer, can be pulverized in production-scale in order to meet the required quality parameters and to guarantee an optimum adaptation of the system to the feed material.

- - - - - - - - - - - - - - - - - - - - - -

Pallmann is a leading manufacturer of machines and systems for the size reduction of most different materials, mainly for the wood-, plastics-, chemical-, pharmaceutical- foodstuff-, mineral- and recycling industries.

The company employs approximately 400 people worldwide and has an international sales- and service network that consists of sales- and representative offices.

The Pallmann headquarters is located in Zweibrücken/Germany where they also operate the world’s largest research and technology center for size reduction techniques.